- What is an Equal Tee?

- Primary Function of the Equal Tee

- How the Equal Tee Works in a Piping System

- Equal Tee vs. Reducing Tee

- Advantages of Using an Equal Tee

- Materials and Manufacturing Standards

- Industrial Applications of Equal Tees

- Equal Tee Design Considerations

- Types of Equal Tees by Connection Method

- Maintenance and Inspection

- Cost Considerations

- Choosing Between Equal Tee and Other Fittings

- Summary of Equal Tee Benefits

- Conclusion

In the construction of piping systems, fittings are essential to ensure proper flow direction, branch creation, and system integrity. Among these fittings, the equal tee is one of the most commonly used and versatile components. It plays a significant role in branching pipelines and maintaining balanced fluid distribution, making it indispensable in industries such as oil and gas, water treatment, chemical processing, and HVAC systems.

This article explores the structure of the equal tee, its core functions, advantages, manufacturing standards, and industrial applications to provide a comprehensive understanding of why it is a preferred choice for many piping projects.

Sunjin Metals Vina (SJM Vina), is a trusted supplier of high-quality steel pipes, flanges, and fittings sourced from South Korea and other countries, fully compliant with international standards.

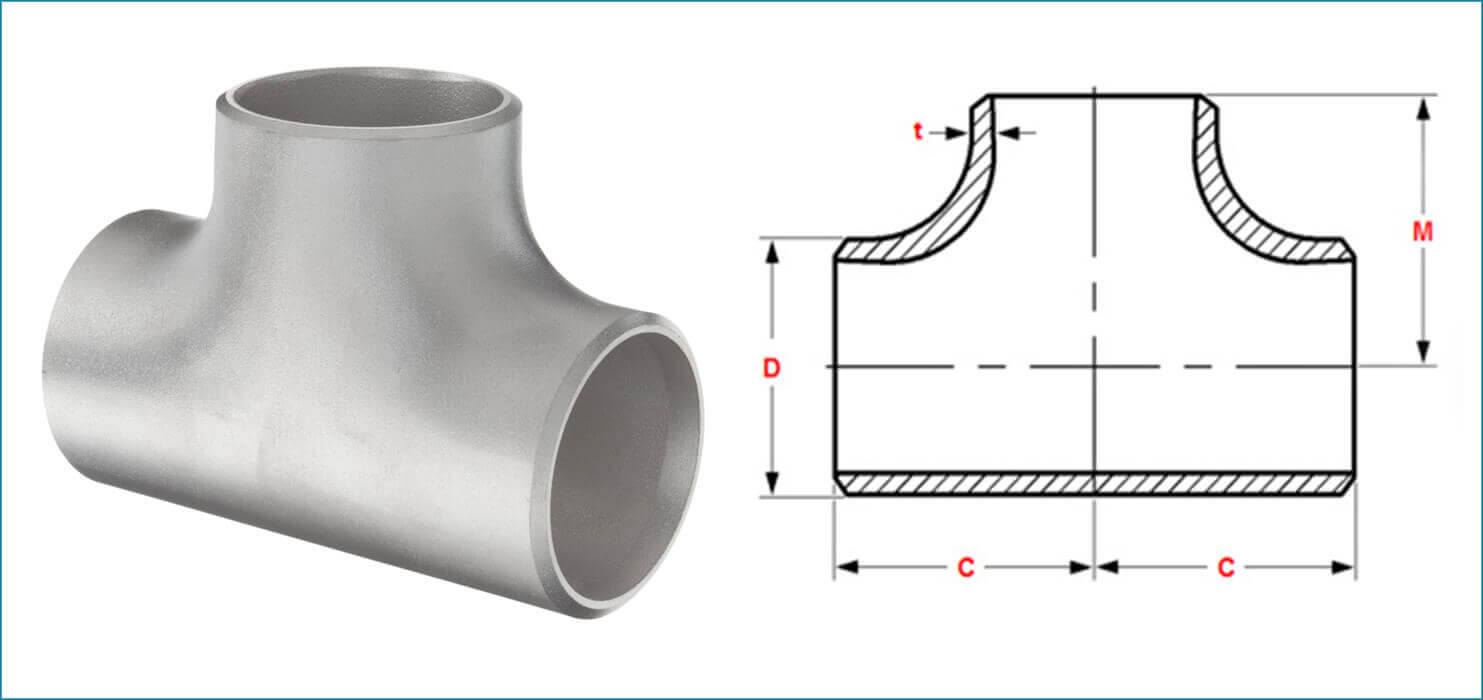

What is an Equal Tee?

An equal tee, sometimes referred to as a straight tee, is a T-shaped pipe fitting with three outlets—one inlet and two outlets, or vice versa—arranged at 90 degrees to each other. All three ends have the same diameter, hence the term “equal.”

Key Features:

-

Three openings of identical size.

-

Allows smooth division or merging of flow.

-

Manufactured in materials such as carbon steel, stainless steel, and alloy steel.

-

Produced according to recognized standards for accuracy and durability.

Primary Function of the Equal Tee

The core function of the equal tee is to split or combine fluid flow in a piping system while maintaining the same pipe diameter in all connected branches.

Main Roles:

-

Flow Distribution: Splits the flow from one inlet into two outlets of equal capacity.

-

Flow Combination: Merges flow from two inlets into a single outlet without changing pipe diameter.

-

Balanced System Design: Ensures pressure and flow rate remain consistent in all directions.

How the Equal Tee Works in a Piping System

When fluid enters through one of the openings of an equal tee, it is directed through the main run and into the branch at a right angle. Because all openings have the same internal diameter, the transition is smooth, reducing turbulence and minimizing pressure drop.

Flow Scenarios:

-

One Inlet, Two Outlets: Used for splitting flow to serve two different destinations.

-

Two Inlets, One Outlet: Used for combining two streams into one, such as in return lines or mixing systems.

Equal Tee vs. Reducing Tee

While an equal tee has all three openings of the same size, a reducing tee has one branch smaller in diameter than the main run. The equal tee’s function focuses on uniform flow capacity, while the reducing tee is used for size reduction in a branch connection.

When to Choose an Equal Tee:

-

When equal flow rates are needed in all branches.

-

When consistent pressure is required.

-

When uniform pipe size simplifies design and fabrication.

Advantages of Using an Equal Tee

-

Uniform Flow Distribution: Maintains equal diameter, preventing bottlenecks.

-

Versatility: Suitable for various media such as liquids, gases, and steam.

-

Structural Integrity: Manufactured to withstand high pressures and temperatures.

-

Ease of Integration: Compatible with standardized pipe sizes and fittings.

-

Durability: Made from high-quality materials for long service life.

Materials and Manufacturing Standards

Common Materials:

-

Carbon Steel: Used in high-pressure and high-strength applications.

-

Stainless Steel: Provides excellent corrosion resistance in chemical and marine environments.

-

Alloy Steel: Suitable for high-temperature services.

Standards:

-

ASME B16.9: Factory-made wrought buttwelding fittings.

-

MSS SP-75: High-strength buttweld fittings for pipeline systems.

-

DIN and ISO: Standards for international projects.

Industrial Applications of Equal Tees

1. Oil and Gas Industry

Equal tees are used in crude oil pipelines, gas distribution networks, and refinery systems to distribute product evenly between different processing units.

2. Chemical Processing

In chemical plants, equal tees connect pipelines carrying acids, solvents, or steam, ensuring consistent distribution to various reaction vessels.

3. Water Supply and Treatment

Municipal water systems use equal tees for branching supply lines to different areas while maintaining equal flow capacity.

4. HVAC Systems

In heating, ventilation, and air conditioning systems, equal tees distribute hot or cold water evenly between different circuits.

5. Food and Beverage Industry

Hygienic stainless steel equal tees are used for clean, sanitary branching in processing lines.

Equal Tee Design Considerations

-

Wall Thickness: Must match the schedule of the connected pipes for pressure compatibility.

-

Weld Preparation: For butt-weld types, ends are beveled to allow strong welding joints.

-

Alignment: Precise alignment during installation avoids flow disruptions.

-

Corrosion Protection: Material choice should match the fluid’s corrosiveness.

Types of Equal Tees by Connection Method

-

Butt-Weld Equal Tee: Provides strong, leak-resistant joints; ideal for permanent installations.

-

Socket Weld Equal Tee: Common in small-diameter, high-pressure applications.

-

Threaded Equal Tee: Allows for quick assembly and disassembly without welding.

Maintenance and Inspection

Regular maintenance is essential for ensuring the long-term performance of equal tees. Inspections should focus on:

-

Weld integrity and signs of fatigue.

-

Corrosion, especially in chemical service.

-

Erosion from high-velocity fluids.

-

Proper sealing in threaded or socket weld connections.

Cost Considerations

The cost of an equal tee depends on:

-

Material type (carbon steel is more economical than stainless steel).

-

Size and pressure class.

-

Manufacturing method (seamless tees cost more than welded tees).

Although equal tees may cost slightly more than simple couplings or elbows, their ability to maintain balanced flow in a system provides long-term operational benefits.

Choosing Between Equal Tee and Other Fittings

When designing a piping system, the decision to use an equal tee should consider:

-

Whether flow needs to be split or merged.

-

The need for uniform pipe diameter across all outlets.

-

Pressure and temperature requirements.

-

Space and layout constraints.

If the application requires size reduction, a reducing tee is more appropriate; if only a directional change is needed, elbows may be better.

Summary of Equal Tee Benefits

-

Simple yet effective for branching pipelines.

-

Maintains equal flow rates and pressure in all directions.

-

Compatible with various industrial systems and media.

-

Easy integration due to standardized sizes and manufacturing.

-

Reliable performance under high-stress operating conditions.

Conclusion

The function of the equal tee is straightforward yet essential: it allows for the branching or combining of flow in piping systems while maintaining the same pipe diameter across all outlets. This ensures balanced distribution, consistent pressure, and reliable system performance in industries ranging from oil and gas to water treatment and HVAC.

Sunjin Metals Vina provides high-quality equal tees manufactured to international standards, ensuring durability, precision, and performance in even the most demanding applications. Contact us at +84 33 4233 127 or via email at sjmvina@sunjinmetal.com. Visit www.sjmvina.com.vn for more information and to place your order today!

Số lần xem: 62