In industries operating in marine and coastal environments, the durability and resistance of materials to corrosion are critical factors in ensuring safety and long-term performance. Among the most essential components in pipeline systems for marine applications are steel flanges, which connect pipes, valves, and fittings. For environments exposed to seawater, Korean steel flanges have proven to be an optimal solution due to their superior quality, corrosion resistance, and compliance with international standards.

The Role of Flanges in Marine Pipeline Systems

Flanges are mechanical components designed to connect pipes and fittings in a secure and detachable way. In marine systems, they must withstand constant exposure to seawater, high salinity, and varying temperatures. Poor-quality flanges or materials unsuitable for saltwater environments often lead to premature failure, leaks, and increased maintenance costs.

Korean steel flanges stand out in this regard, manufactured under strict quality standards and using premium alloys designed to resist seawater corrosion. Their role goes beyond simple pipe connection — they ensure the safety, integrity, and efficiency of the entire piping system.

Why Choose Korean Steel Flanges for Saltwater Environments?

There are several key reasons why Korean steel flanges are widely chosen for marine and offshore applications:

-

High Corrosion Resistance

Korean manufacturers utilize advanced metallurgy and surface treatment processes, ensuring superior resistance to seawater’s corrosive elements such as chlorides and sulfates. This reduces the risk of rust, pitting, and surface degradation. -

International Quality Standards

Flanges produced in Korea comply with major global standards such as ANSI/ASME, JIS, DIN, and KS. This guarantees compatibility in diverse engineering projects and assures end-users of product reliability. -

Durability and Longevity

By using carefully selected steel grades such as carbon steel, stainless steel (304, 316, duplex), and alloy steels, Korean flanges are engineered for high mechanical strength and long service life in harsh marine conditions. -

Precision Manufacturing

Korean suppliers invest heavily in CNC machining, forging, and heat treatment technology, which ensures dimensional accuracy, tight tolerances, and optimal sealing performance. -

Trusted Global Reputation

Korean steel products, including pipes, flanges, and fittings, have established a strong reputation worldwide for reliability and cost-effectiveness. Many international marine and offshore projects prefer Korean materials over other origins.

Applications of Korean Steel Flanges in Saltwater Industries

Korean steel flanges are extensively used in industries where seawater exposure is unavoidable:

-

Offshore Oil & Gas Platforms: Essential for pipeline connections transporting crude oil, natural gas, and chemicals in offshore rigs.

-

Shipbuilding and Marine Engineering: Used in ship piping systems, ballast water management, and desalination plants.

-

Coastal Power Plants: Flanges connect pipelines for seawater cooling systems in thermal and nuclear power plants.

-

Seawater Treatment Facilities: Widely applied in desalination plants and wastewater treatment projects along coastal areas.

-

Marine Infrastructure: Utilized in harbors, docks, and coastal industrial facilities requiring durable pipeline systems.

Materials and Grades for Marine-Resistant Flanges

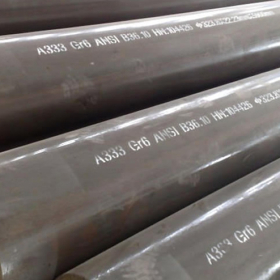

Depending on the specific requirements of the project, Korean steel flanges are available in various materials:

-

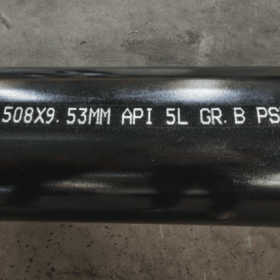

Carbon Steel Flanges (A105, A350 LF2): Widely used in general pipelines but may require protective coatings for marine use.

-

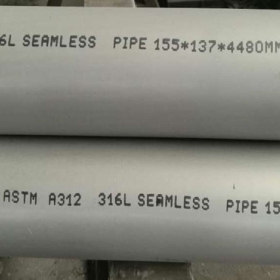

Stainless Steel Flanges (304, 316, 316L, Duplex 2205): Excellent resistance to seawater, with 316 and Duplex being particularly suitable for high-salinity environments.

-

Alloy Steel Flanges (F5, F9, F11): Designed for higher pressure and temperature conditions.

Among these, stainless steel 316 and duplex steel 2205 flanges from Korea are considered the best choices for long-term seawater resistance.

Advantages of Partnering with Sunjin Metals Vina (SJM Vina)

As a trusted supplier of Korean-origin steel products in Vietnam, Sunjin Metals Vina (SJM Vina) offers:

-

High-Quality Korean Steel Products: Direct imports from leading Korean mills.

-

Comprehensive Supply: Steel pipes, flanges, and fittings suitable for a wide range of applications.

-

Technical Expertise: Consultation and support for selecting the right materials for marine and industrial projects.

-

Reliable Delivery: Strong logistics and inventory to meet urgent project demands.

-

Competitive Pricing: Cost-effective solutions without compromising quality.

With headquarters in Ho Chi Minh City, Sunjin Metals Vina is committed to providing high-quality Korean steel solutions tailored to the needs of oil & gas, shipbuilding, power generation, and water treatment industries.

Conclusion

In environments where seawater exposure is a constant challenge, choosing the right flange material is crucial. Korean steel flanges offer outstanding corrosion resistance, durability, and compliance with international standards, making them the preferred choice for marine and offshore applications.

At Sunjin Metals Vina (SJM Vina), we are proud to supply Korean-origin steel pipes, flanges, and fittings that meet the rigorous demands of saltwater industries. By combining technical expertise with premium products, we ensure our clients achieve long-lasting and reliable performance in every project.

📍 Company Information

Sunjin Metals Vina (SJM Vina)

628 Le Hong Phong Street, Ward 10, District 10, Ho Chi Minh City, Vietnam

Hotline: +84 33 4233 127

Email: sjmvina@sunjinmetal.com

Website: www.sjmvina.com.vn

Số lần xem: 114