Introduction

In industrial piping systems, flanges play a critical role by securely connecting pipes, valves, pumps, and other equipment. They ensure tight sealing, mechanical stability, and easy disassembly for maintenance.

To guarantee proper identification and compliance with international standards, every flange is marked with detailed information, including standard, pressure rating, material, and manufacturing data. These markings are not just identification codes – they are essential for quality control, traceability, and system safety.

In this article, Sunjin Metals Vina (SJM Vina) – a trusted supplier of Korean-origin steel pipes, flanges, and fittings – will provide an in-depth yet easy-to-understand explanation of common flange markings, their meanings, and why they matter in design, procurement, and maintenance of piping systems.

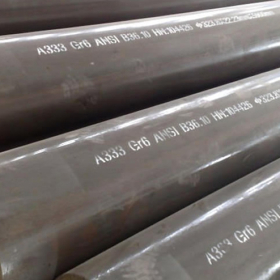

1. Standard or Specification

Each flange is manufactured according to a specific international or national standard, which defines its dimensions, tolerances, pressure ratings, and material requirements. Some of the most widely recognized standards include:

-

ASME B16.5 – American standard for pipe flanges and flanged fittings.

-

ASME B16.47 – Standard for large diameter flanges (Series A & B).

-

EN 1092-1 – European standard for steel flanges.

-

DIN 2501 – German industrial standard.

-

JIS B2220 – Japanese Industrial Standard.

-

GB/T 9119-2010 – Chinese standard for steel flanges.

Each standard determines bolt hole arrangement, gasket compatibility, and material selection criteria. Reading and understanding the standard marking ensures that the flange will properly match the pipeline and meet the project’s engineering requirements.

2. Nominal Diameter (DN/NPS)

The nominal diameter (DN or NPS) indicates the bore size of the flange – corresponding to the inner diameter of the pipe it connects to.

-

DN (Diameter Nominal) is used in the metric system (millimeters).

-

NPS (Nominal Pipe Size) is used in the imperial system (inches).

For example, DN100 corresponds to NPS 4”, which means both fit a pipe with a nominal diameter of 100 mm (4 inches).

Correctly identifying DN or NPS ensures dimensional compatibility between pipes, flanges, and fittings.

3. Pressure Rating (PN/Class)

The pressure rating defines the maximum internal pressure that a flange can safely withstand during operation.

Two main systems are used worldwide:

-

PN (Pressure Nominal) – used in European and metric standards, measured in bar or MPa (e.g., PN10, PN16, PN25, PN40, PN100).

-

Class – used in American standards, measured in psi (e.g., Class 150, 300, 600, 900, 1500, 2500).

Selecting the correct pressure rating is essential to ensure safe operation and prevent leakage or mechanical failure under pressure.

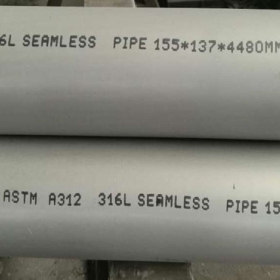

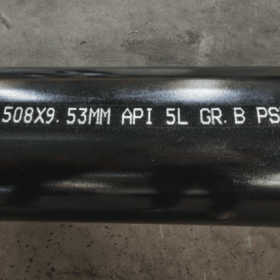

4. Material Specification

Flanges are manufactured from different materials depending on service conditions, such as temperature, pressure, and chemical exposure.

Common material markings include:

-

Carbon Steel: A105, A350 LF2

-

Stainless Steel: A182 F304, A182 F316, A182 F321

-

Alloy Steel: A182 F11, A182 F22

Each material grade has its own properties – carbon steel for general applications, stainless steel for corrosion resistance, and alloy steel for high-temperature or high-pressure services. Understanding these markings helps engineers select the right flange for each environment.

5. Face Type and Surface Finish

The flange face type determines how it seals with the gasket. Common types include:

-

RF (Raised Face): the most widely used, suitable for general-purpose gaskets.

-

FF (Flat Face): provides full gasket contact, ideal for low-pressure applications.

-

RTJ (Ring Type Joint): designed for high-pressure and high-temperature services.

Additionally, the surface finish of the sealing face (measured in AARH) affects gasket grip and sealing performance. For example, 125 AARH or 250 AARH indicates the surface roughness level per ASME standards.

6. Manufacturer Identification and Heat Number

To ensure traceability and quality assurance, each flange is marked with identification details such as:

-

Manufacturer’s name or logo

-

Heat Number: a unique code that links the flange to the specific steel batch used.

-

Lot Number: used for production tracking and quality control.

These markings enable complete traceability throughout the manufacturing process – a vital requirement in quality management systems for oil & gas, petrochemical, and construction industries.

7. Additional Information

Additional markings may also appear on the flange body, such as:

-

Country of origin (e.g., Korea, Japan, EU)

-

Year of manufacture

-

Surface coating or treatment, such as galvanizing, epoxy coating, or PTFE coating for corrosion resistance

These details provide end users with full visibility into the product’s technical characteristics and origin.

Importance of Understanding Flange Markings

Flange markings are not just manufacturing codes – they are essential information for the safe and efficient operation of a piping system.

Proper understanding helps:

-

Ensure technical compatibility between pipes, fittings, and valves.

-

Prevent leakage or system failure due to mismatch or incorrect selection.

-

Support inspection and documentation during audits or certification.

-

Facilitate maintenance and replacement through material traceability.

At Sunjin Metals Vina (SJM Vina), we understand that every detail matters in industrial piping. Our Korean-origin steel pipes, flanges, and fittings are manufactured under strict quality control following international standards such as ASME, JIS, and EN 1092, ensuring excellent durability, precision, and corrosion resistance for diverse applications — from oil & gas and petrochemical plants to water treatment and infrastructure projects.

Conclusion

Flange markings serve as a universal technical language that communicates vital information about a flange’s design, material, and performance capabilities.

By understanding these markings, engineers, procurement teams, and maintenance personnel can make informed decisions — ensuring system safety, reliability, and long-term efficiency.

If you are looking for high-quality Korean steel flanges, pipes, and fittings that meet international standards, contact us today:

SUNJIN METALS VINA CO., LTD (SJM Vina)

📍 Address: 628 Le Hong Phong, Ward 10, District 10, Ho Chi Minh City, Vietnam

📞 Hotline: +84 33 4233 127

✉️ Email: sjmvina@sunjinmetal.com

🌐 Website: www.sjmvina.com.vn

Số lần xem: 128