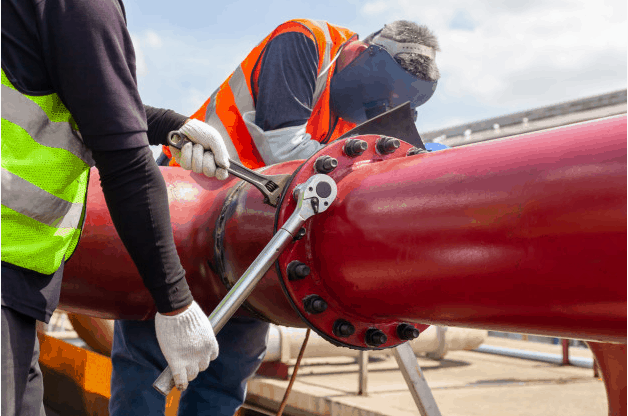

Flange bolting plays a critical role in ensuring the integrity of piping systems. Improper installation is the most common cause of leaking joints, which can lead to costly downtime, safety risks, and operational inefficiencies. At Sunjin Metals Vina (SJM Vina), we provide Korean-origin steel pipes, flanges, and fittings for industrial projects, and we emphasize that proper flange bolting procedures must always be followed. Below is a comprehensive guide to the correct procedure for flange bolting.

1. Cutting of Soft Gaskets

-

Punch or cut bolt holes slightly larger than the bolts to ensure proper seating.

-

Never cut a gasket by hammering against the flange surface.

-

Always use a proper gasket cutter to achieve the exact size.

-

Ensure the inside diameter of the gasket is not smaller than the inside diameter of the pipeline to prevent flow obstruction.

2. Handling of Gaskets

-

Carry and store gaskets carefully to avoid bending or damaging them.

-

Large-diameter metallic and semi-metallic gaskets should be transported with proper packing or mounting boards.

3. Tools and Cleaning

-

Clean flange surfaces and fasteners thoroughly before installation.

-

Use wire brushes or brass scrapers to remove debris, rust, or gasket residue.

-

Flange spreaders may be required to open gaps for cleaning.

-

Ensure all torque wrenches and tensioning tools are properly calibrated.

4. Visual Inspection

-

Inspect bolts, nuts, and washers for cracks, burrs, or other defects.

-

Check flange faces for warping or scoring to confirm flatness and parallelism.

-

Ensure the correct gasket type, size, and thickness is selected and is free from damage.

5. Lubrication

-

Apply suitable lubricant (oil and graphite mix recommended) to fastener threads, nut bearing surfaces, and washers.

-

Proper lubrication reduces friction and ensures even distribution of bolt load.

-

Avoid contaminating gasket or flange faces with lubricant.

6. Gasket Installation

-

Place the gasket carefully between flanges and ensure it is centered.

-

Do not use tape, jointing compounds, or release agents.

-

If temporary fixing is needed, use a light spray adhesive.

7. Bolt Tightening Sequence

Achieving correct bolt load is essential: low enough to avoid gasket damage, but high enough to ensure sealing.

-

Always use a torque wrench or controlled-tensioning device.

-

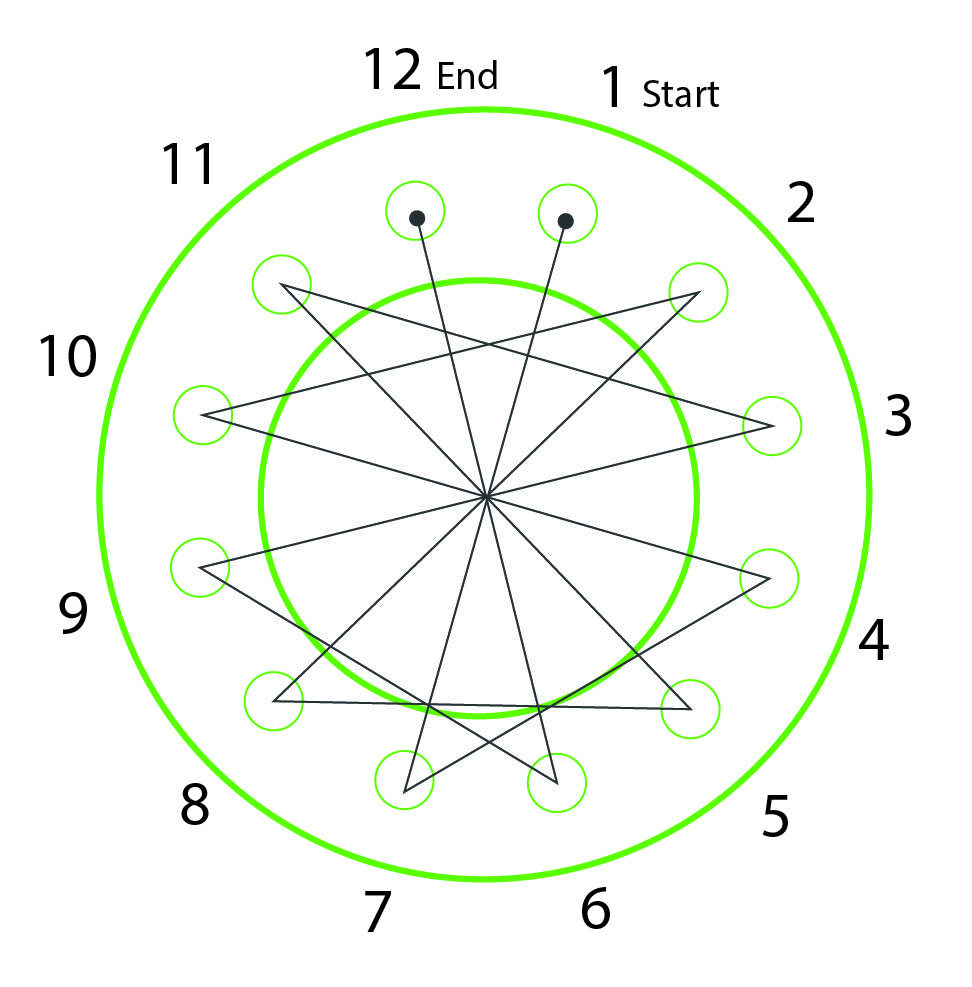

Tighten bolts using the cross-bolting pattern in multiple passes:

-

Pass 1: Hand-tighten bolts in cross pattern.

-

Pass 2: Torque to ~30% of final value.

-

Pass 3: Torque to ~60%.

-

Pass 4: Torque to 100%.

-

Pass 5: Repeat at full torque, clockwise around the flange.

-

Repeat the final pass until no further nut movement is observed. Hydraulic tensioners or heating methods may also be used for large bolts.

8. Re-Tightening

-

Due to material relaxation, bolts may require re-tightening after 24 hours at ambient temperature.

-

Do not re-torque elastomer-based asbestos-free gaskets after exposure to high temperatures, as embrittlement may occur.

9. Storage of Gaskets

-

Store gaskets flat, in a cool and dry place, away from sunlight, water, and chemicals.

-

Avoid hanging soft gaskets as they may deform.

-

Graphite and PTFE gaskets have an almost indefinite shelf life, but elastomer-based gaskets should not be used after 5 years.

10. Additional Technical Considerations

-

Flange Insulation Sets: Installed to prevent electrical current flow in pipelines.

-

Direct Tension Indicators (DTI): Provide visual proof of correct bolt load.

-

Gasket Reuse: Reusing gaskets is not recommended as sealing ability is compromised.

-

Spacer Rings: Recommended instead of stacking multiple gaskets to fill gaps.

-

Hydrostatic Testing: Requires higher bolt stresses and sometimes high-strength alloy bolts.

11. Common Wrong Practices

Avoid the following:

-

Reusing old gaskets.

-

Storing gasket sheets vertically.

-

Cleaning flanges with chisels or saw blades.

-

Cutting gaskets by hammering against flanges.

-

Using multiple gaskets to fill gaps.

-

Applying grease on gasket faces.

-

Using ordinary or rusted fasteners without lubrication.

-

Incorrect tightening sequence.

Conclusion

Correct flange bolting procedures are essential for safe, leak-free, and efficient piping systems. By following proper steps in gasket handling, flange cleaning, bolt tightening, and inspection, the risk of leaks and costly maintenance is significantly reduced.

At Sunjin Metals Vina (SJM Vina), we are committed to providing high-quality steel pipes, flanges, and fittings of Korean origin that meet international standards. Our expertise ensures that industrial clients receive not only reliable products but also technical guidance for optimal performance.

📍 Sunjin Metals Vina (SJM Vina)

628 Le Hong Phong, Ward 10, District 10, Ho Chi Minh City, Vietnam

📞 Hotline: +84 33 4233 127

📧 Email: sjmvina@sunjinmetal.com

🌐 Website: www.sjmvina.com.vn

Số lần xem: 121