Pipe Wall Thickness Calculator (ASME B31.3)

Tính độ dày thành ống

Công thức tính độ dày thành ống theo ASME B31.3

t = (P × D) / (2 × (S × E × W + P × Y)) + C

Trong đó:

- t: Độ dày thành ống tối thiểu (mm hoặc in)

- P: Áp suất thiết kế (MPa hoặc psi)

- D: Đường kính ngoài ống (OD, mm hoặc in)

- S: Ứng suất cho phép (MPa hoặc psi)

- E: Hệ số mối hàn (liền mạch E=1.0; hàn E=0.6–0.85)

- W: Hệ số giảm ứng suất (thường =1.0)

- Y: Hệ số vật liệu (thép ≈ 0.4)

- C: Dung sai ăn mòn (1–3 mm)

Tiêu chuẩn ASME B31.3 đảm bảo độ dày ống đủ để chịu áp suất thiết kế, đồng thời tính đến ăn mòn, hàn và nhiệt độ.

Sunjin Metals Vina cung cấp ống thép, mặt bích và phụ kiện đạt tiêu chuẩn ASME B31.3. Liên hệ hotline +84 33 4233 127 hoặc email sjmvina@sunjinmetal.com để được tư vấn.

Số lần xem: 89

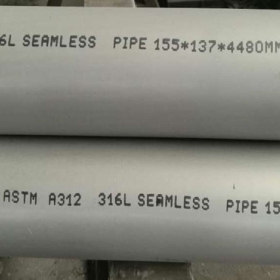

In the industrial metal supply sector, 316L stainless steel is among the most preferred grades due to its exceptional corrosion resistance. However, when examining technical specifications, users often encounter two designations: TP316L and 316L. While both are low-carbon variants of the popular 316 grade, subtle yet critical differences exist between them that directly impact operational performance in real-world applications. At Sunjin Metals Vina (SJM Vina), we specialize in importing stainless steel pipes, flanges, and fittings from South Korea and Japan, helping our clients understand material nuances to make the most accurate choice.

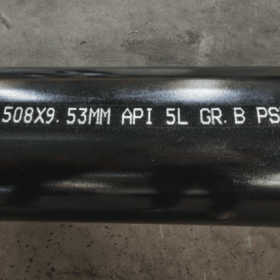

API 5L Grade B steel pipe is one of the most widely used materials in the oil and gas industry, prized for its perfect balance of strength and workability. One of the most critical factors when selecting steel pipes for any project is understanding the pressure rating. This rating is not a fixed value but varies based on wall thickness, diameter, and the manufacturing process. At Sunjin Metals Vina (SJM Vina), we specialize in importing and supplying high-quality API 5L Grade B pipes from South Korea, Japan, and other reputable nations, ensuring compliance with the most rigorous technical standards for our clients' operational systems.

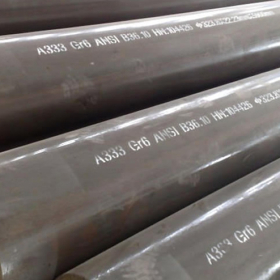

In the piping industry, selecting the correct material standard is a critical factor that determines the safety and longevity of a system. Among the most common standards today, A106 and A333 are two specifications that frequently cause confusion for users. Although both are industrial steel pipes, they possess entirely different chemical and mechanical properties. Sunjin Metals Vina (SJM Vina), a specialist in importing steel pipes and fittings from South Korea and Japan, shares the following in-depth insights to help you distinguish between these two materials.

Pipelines serve as the indispensable backbone of the oil and gas industry, ensuring the secure and continuous transport of vital fluids. From crude oil and natural gas to refined petroleum products, robust piping infrastructure facilitates the movement of energy essentials from extraction sites to refineries and ultimately to the global market. At Sunjin Metals Vina (SJM Vina), we understand that selecting the appropriate pipe material is critical to project integrity. SJM Vina specializes in importing high-grade steel pipes, flanges, and fittings from South Korea, Japan, and other leading industrial nations to provide optimized solutions for your infrastructure needs.

In the field of civil and industrial engineering, SGP steel pipe is one of the most widely used materials due to its versatility and reliability in low-pressure fluid conveyance. At Sunjin Metals Vina (SJM Vina), we provide a comprehensive range of SGP steel pipes imported directly from Japan, South Korea, and other reputable markets, ensuring superior quality for every project.

In the oil, gas, and energy transportation industries, selecting the right piping is a decisive factor for both operational efficiency and project safety. API 5L steel pipes are the industry standard, recognized for their superior load-bearing capacity and durability in extreme environments. At Sunjin Metals Vina (SJM Vina), we specialize in importing and distributing high-quality API 5L pipes from South Korea, Japan, and other leading manufacturing nations, meeting the most rigorous technical demands of our clients.

ASTM A105 is the standard specification for forged carbon steel components developed by the American Society for Testing and Materials (ASTM). This material is designed exclusively for the manufacture of piping system components such as flanges, valves, and high-pressure fittings.

In industrial piping systems, flanges play a critical role by securely connecting pipes, valves, pumps, and other equipment. They ensure tight sealing, mechanical stability, and easy disassembly for maintenance.

To guarantee proper identification and compliance with international standards, every flange is marked with detailed information, including standard, pressure rating, material, and manufacturing data. These markings are not just identification codes – they are essential for quality control, traceability, and system safety.

In modern hydraulic systems, where fluids are transmitted under extreme pressure, every component plays a vital role in ensuring overall performance and safety. Among these components, steel flanges are indispensable. They are used to connect pipes, valves, pumps, and other equipment, creating a secure and leak-proof joint that withstands both high pressure and temperature.

Today, Korean steel flanges have gained strong recognition in the industrial market thanks to their superior quality, durability, and compliance with strict international standards. Their exceptional ability to endure high pressure makes them an ideal solution for hydraulic systems and other demanding industrial applications.

In industries operating in marine and coastal environments, the durability and resistance of materials to corrosion are critical factors in ensuring safety and long-term performance. Among the most essential components in pipeline systems for marine applications are steel flanges, which connect pipes, valves, and fittings. For environments exposed to seawater, Korean steel flanges have proven to be an optimal solution due to their superior quality, corrosion resistance, and compliance with international standards.

In modern industries, pipeline systems are required to operate under increasingly complex and demanding conditions. From oil and gas, petrochemicals, power plants, to marine engineering, the performance and safety of pipeline connections play a critical role in ensuring stability and minimizing risks. Among the essential components of these systems, Korean steel flanges stand out for their superior leak-proof properties in high-pressure environments, helping businesses optimize operations while ensuring compliance with safety standards.

In industrial systems, especially in the oil and gas, energy, chemical, and construction sectors, steel flanges play a vital role in connecting pipelines, equipment, and valves. To ensure safety and operational efficiency, flange products must strictly comply with national and international quality standards. Among these, the KS (Korean Standards) system stands out as a benchmark widely applied to Korean steel flanges, ensuring stability, safety, and long-term durability.

In industrial systems, boilers play a crucial role in generating steam, heat, and energy for various production processes. These systems operate under extreme conditions, including high temperatures, elevated pressure, and long continuous working hours. Therefore, all piping materials and connection components must meet strict standards of strength, durability, and safety.

In industrial piping systems, pipe fittings play a vital role in connecting pipelines, changing flow direction, branching, or adjusting pressure. To ensure safety, efficiency, and durability, these fittings must comply with strict international and regional standards. Among them, KS (Korean Standards), JIS (Japanese Industrial Standards), and ASTM (American Society for Testing and Materials) are the three most recognized systems applied to Korean pipe fittings.

At Sunjin Metals Vina (SJM Vina), we specialize in supplying Korean steel pipes, Korean steel flanges, and Korean pipe fittings, all manufactured in compliance with these standards to serve key industries such as oil & gas, chemical processing, power generation, and construction.

In the oil & gas sector, steel pipes and pipeline accessories form the foundation of safe, durable, and efficient pipeline systems. Among them, Korean steel flanges are highly valued for their superior quality, precise manufacturing, and ability to meet stringent international standards.

At Sunjin Metals Vina (SJM Vina), we specialize in supplying Korean steel pipes, Korean steel flanges, and Korean pipe fittings, serving industrial projects, especially in the oil & gas industry, with a strong commitment to quality and professional service.