In modern hydraulic systems, where fluids are transmitted under extreme pressure, every component plays a vital role in ensuring overall performance and safety. Among these components, steel flanges are indispensable. They are used to connect pipes, valves, pumps, and other equipment, creating a secure and leak-proof joint that withstands both high pressure and temperature.

Today, Korean steel flanges have gained strong recognition in the industrial market thanks to their superior quality, durability, and compliance with strict international standards. Their exceptional ability to endure high pressure makes them an ideal solution for hydraulic systems and other demanding industrial applications.

1. The Role of Steel Flanges in Hydraulic Systems

In hydraulic systems, energy is transmitted through pressurized fluids—most commonly hydraulic oil. These systems operate under extremely high pressures, and all components must be tightly connected to ensure safety and efficiency.

Steel flanges are used as mechanical connectors that join pipes and equipment together. A typical flange assembly includes two flange faces, bolted together with a gasket in between to ensure a tight seal. This structure allows for easy assembly and disassembly during maintenance, while maintaining the system’s ability to handle high pressure without leakage.

A high-quality flange must meet key performance criteria such as:

-

Excellent pressure resistance

-

Reliable sealing capability

-

Mechanical strength and durability under vibration

-

Corrosion and heat resistance

These properties make steel flanges an essential component in maintaining the stability and longevity of hydraulic systems.

2. Superior Advantages of Korean Steel Flanges

Korean steel flanges are manufactured using advanced forging and machining technologies, under strict quality control systems that comply with global standards like ANSI, JIS, DIN, and KS. Several technical advantages set them apart from conventional products:

2.1. Exceptional Pressure Resistance

Thanks to precise forging and heat treatment processes, Korean flanges possess a dense internal grain structure that provides excellent mechanical strength. They can withstand extremely high pressures without deformation, making them ideal for heavy-duty hydraulic applications.

2.2. Excellent Sealing and Safety

Korean steel flanges are designed to achieve maximum sealing performance. The machined contact surfaces ensure even pressure distribution across the gasket, minimizing the risk of leaks. This reliability is critical in high-pressure hydraulic systems where even minor leakage can cause serious operational issues.

2.3. High-Quality Steel Materials

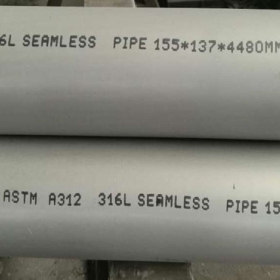

Manufacturers in Korea use premium-grade materials such as carbon steel, stainless steel (304/316), and alloy steel. These materials are chosen for their strength, heat tolerance, and crack resistance. As a result, Korean steel flanges perform consistently even in extreme working environments.

2.4. Corrosion and Heat Resistance

Hydraulic systems often operate under varying temperatures and in contact with chemical fluids. Korean flanges are either made from corrosion-resistant stainless steel or coated with protective layers to prevent oxidation, ensuring long service life and stable operation.

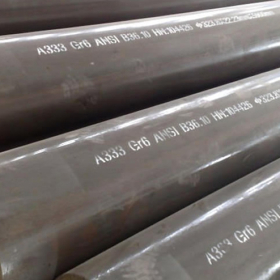

2.5. Compliance with International Standards

Korean steel flanges meet major global standards including ASME B16.5, JIS B2220, and DIN EN 1092-1. This ensures seamless integration with industrial piping systems worldwide, providing versatility and compatibility across different projects.

3. Applications of Korean Steel Flanges in Hydraulic Systems

Due to their outstanding pressure resistance and durability, Korean steel flanges are widely used in various high-pressure applications, including:

-

Hydraulic machinery and metal forming equipment

-

Power transmission systems in manufacturing plants

-

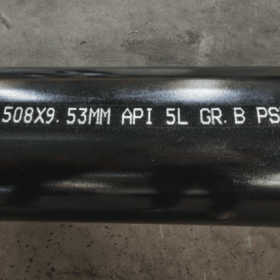

Oil and gas pipelines and industrial fluid systems

-

Heavy-duty machinery and energy infrastructure requiring robust pipe connections

Their ability to maintain stability under continuous pressure fluctuations makes them a preferred choice for engineers and system designers in hydraulic and mechanical industries.

4. Sunjin Metals Vina – Trusted Supplier of Korean Steel Pipes, Flanges, and Fittings

Sunjin Metals Vina (SJM Vina) is a professional supplier specializing in Korean-origin steel pipes, flanges, and pipe fittings for industrial applications in Vietnam.

With a strong partnership network in South Korea, Sunjin Metals Vina provides high-quality materials backed by full CO and CQ certificates, meeting international standards for safety and performance.

Our products include:

-

Korean Steel Pipes: welded, seamless, stainless steel, and carbon steel pipes.

-

Korean Steel Flanges: Weld Neck, Slip On, Blind, Socket Weld, Threaded, and more.

-

Korean Pipe Fittings: elbows, tees, reducers, couplings, and other connection accessories.

Beyond supplying materials, Sunjin Metals Vina also offers technical consulting services to help clients select the right flange and piping solutions for their specific hydraulic or industrial systems, particularly those operating under high pressure.

5. Conclusion

In hydraulic systems where pressure stability and safety are paramount, Korean steel flanges represent a reliable and high-performance solution. They combine superior strength, precise machining, corrosion resistance, and international standard compliance — ensuring long-term durability and leak-free performance.

As a leading supplier of Korean steel pipes, flanges, and fittings in Vietnam, Sunjin Metals Vina is committed to delivering top-quality materials and professional services for diverse industrial projects. We provide solutions that not only meet technical requirements but also enhance system efficiency and operational safety for our customers.

Contact Information

SUNJIN METALS VINA (SJM VINA)

Address: 628 Le Hong Phong Street, Ward 10, District 10, Ho Chi Minh City, Vietnam

Hotline: +84 33 4233 127

Email: sjmvina@sunjinmetal.com

Website: www.sjmvina.com.vn