Introduction

In modern industries, pipeline systems are required to operate under increasingly complex and demanding conditions. From oil and gas, petrochemicals, power plants, to marine engineering, the performance and safety of pipeline connections play a critical role in ensuring stability and minimizing risks. Among the essential components of these systems, Korean steel flanges stand out for their superior leak-proof properties in high-pressure environments, helping businesses optimize operations while ensuring compliance with safety standards.

At Sunjin Metals Vina (SJM Vina), we specialize in supplying high-quality Korean-origin steel pipes, flanges, and pipe fittings, ensuring reliability for projects in Vietnam and other regional markets.

The Role of Flanges in High-Pressure Systems

In pipeline systems, flanges serve as connectors that allow pipes, valves, and equipment to be assembled or disassembled conveniently. In high-pressure environments, the risk of leakage increases significantly due to internal pressure and fluctuations in temperature. Flanges must therefore ensure two key requirements:

-

Tight sealing – preventing leakage of liquids or gases.

-

Mechanical strength – withstanding the effects of pressure and maintaining long-term durability.

Korean steel flanges are designed and manufactured according to international standards such as KS, ANSI, JIS, and DIN, ensuring high precision in dimensions and sealing surfaces. These characteristics make them particularly suitable for use in harsh operating conditions where absolute leak prevention is required.

Why Korean Steel Flanges Provide Superior Leak-Proof Performance

1. High-Quality Steel Materials

Korean manufacturers apply advanced metallurgy technologies to produce steel with high tensile strength, excellent toughness, and resistance to corrosion. This ensures that flanges maintain stability even when subjected to high internal pressure or sudden fluctuations.

2. Precision in Machining and Surface Finish

The sealing surface of a flange is one of the most critical factors in preventing leaks. Korean flanges are manufactured with advanced CNC machining, achieving high dimensional accuracy and smooth sealing surfaces. This precision enhances gasket performance and minimizes the risk of leaks caused by imperfections or uneven contact.

3. Strict Compliance with KS and International Standards

Korean steel flanges are certified under KS (Korean Industrial Standards) and comply with other global standards. These certifications guarantee that every product undergoes rigorous inspection, from material selection to final testing, ensuring leak-proof performance and operational reliability.

4. Compatibility with Various Gasket Types

Korean flanges are compatible with multiple gasket types (spiral wound, ring-type joint, graphite, etc.), allowing engineers to select the most suitable sealing solution for specific working conditions. This flexibility improves leak prevention in high-pressure and high-temperature environments.

Applications in High-Pressure Environments

Thanks to their superior leak-proof properties, Korean steel flanges are widely used in systems where safety and reliability are paramount:

-

Oil and Gas Pipelines: Prevent leakage of hydrocarbons and hazardous chemicals during high-pressure transport.

-

Petrochemical Plants: Maintain secure connections in systems with high-temperature and corrosive substances.

-

Power Plants and Boilers: Ensure sealing integrity under continuous high-pressure steam.

-

Marine Engineering: Withstand harsh environments with pressure fluctuations and high salinity.

These applications highlight why Korean steel flanges are trusted by global industries when leak-proof performance is critical.

Long-Term Benefits of Using Leak-Proof Korean Flanges

-

Operational Safety – Reducing the risk of leaks protects workers, equipment, and the environment.

-

Cost Efficiency – Minimizing downtime and leakage-related losses improves overall system efficiency.

-

Extended Service Life – Durability and corrosion resistance lower replacement frequency and maintenance costs.

-

Regulatory Compliance – Meeting strict safety and environmental standards enhances credibility with partners and customers.

Sunjin Metals Vina – Trusted Supplier of Korean Steel Materials

At Sunjin Metals Vina (SJM Vina), we provide a comprehensive range of Korean steel pipes, flanges, and pipe fittings that meet stringent technical requirements for high-pressure and high-temperature environments.

-

Product Range: Weld neck flanges, slip-on flanges, blind flanges, socket weld flanges, threaded flanges, and more.

-

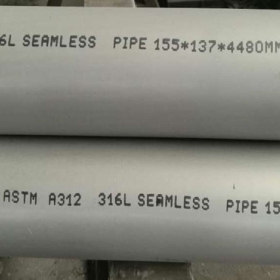

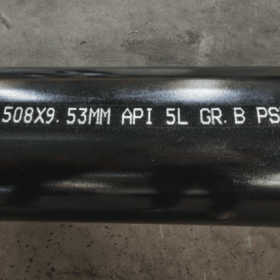

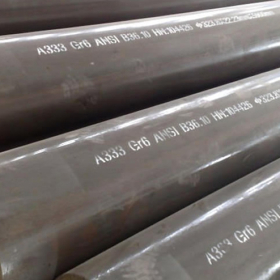

Material Standards: Carbon steel, stainless steel, and alloy steel.

-

Quality Assurance: All products comply with KS, ANSI, JIS, DIN, and EN standards.

-

Technical Support: Our experienced team provides consulting and technical assistance to help clients select the optimal solution for each project.

By partnering with Sunjin Metals Vina, businesses gain access to premium Korean steel products with proven reliability, ensuring safe and efficient pipeline operations.

Conclusion

Leak-proofing is one of the most vital aspects of pipeline safety in high-pressure environments. With outstanding material quality, precise machining, and compliance with international standards, Korean steel flanges provide the optimal solution for industries requiring secure, durable, and reliable connections.

As a trusted supplier, Sunjin Metals Vina (SJM Vina) is committed to delivering high-quality Korean steel pipes, flanges, and fittings, supporting industrial projects in Vietnam with world-class products and technical expertise.

Contact Information

Sunjin Metals Vina (SJM Vina)

📍 Address: 628 Le Hong Phong, Ward 10, District 10, Ho Chi Minh City

📞 Hotline: +84 33 4233 127

✉️ Email: sjmvina@sunjinmetal.com

🌐 Website: www.sjmvina.com.vn

Số lần xem: 128