- What is a Long Weld Neck Flange?

- Dimensions and Standards

- Materials Used in Long Weld Neck Flanges

- Manufacturing Process of Long Weld Neck Flanges

- Applications of Long Weld Neck Flanges

- Advantages of Long Weld Neck Flanges

- Difference Between Weld Neck Flange and Long Weld Neck Flange

- Testing and Quality Assurance

- Future Trends in Flange Technology

- Conclusion

In industrial piping systems, flanges are essential components for connecting pipes, valves, pumps, and other equipment. They ensure safe operation under pressure, allow for disassembly when needed, and provide structural integrity for pipelines carrying gases, liquids, or chemicals. Among the various flange types, the long weld neck flange (LWN flange) stands out as a specialized component designed for high-pressure and high-temperature applications.

This article provides a comprehensive explanation of the long weld neck flange, its design features, benefits, applications, and why it is preferred in specific industries.

Sunjin Metals Vina (SJM Vina), is a trusted supplier of high-quality steel pipes, flanges, and fittings sourced from South Korea and other countries, fully compliant with international standards.

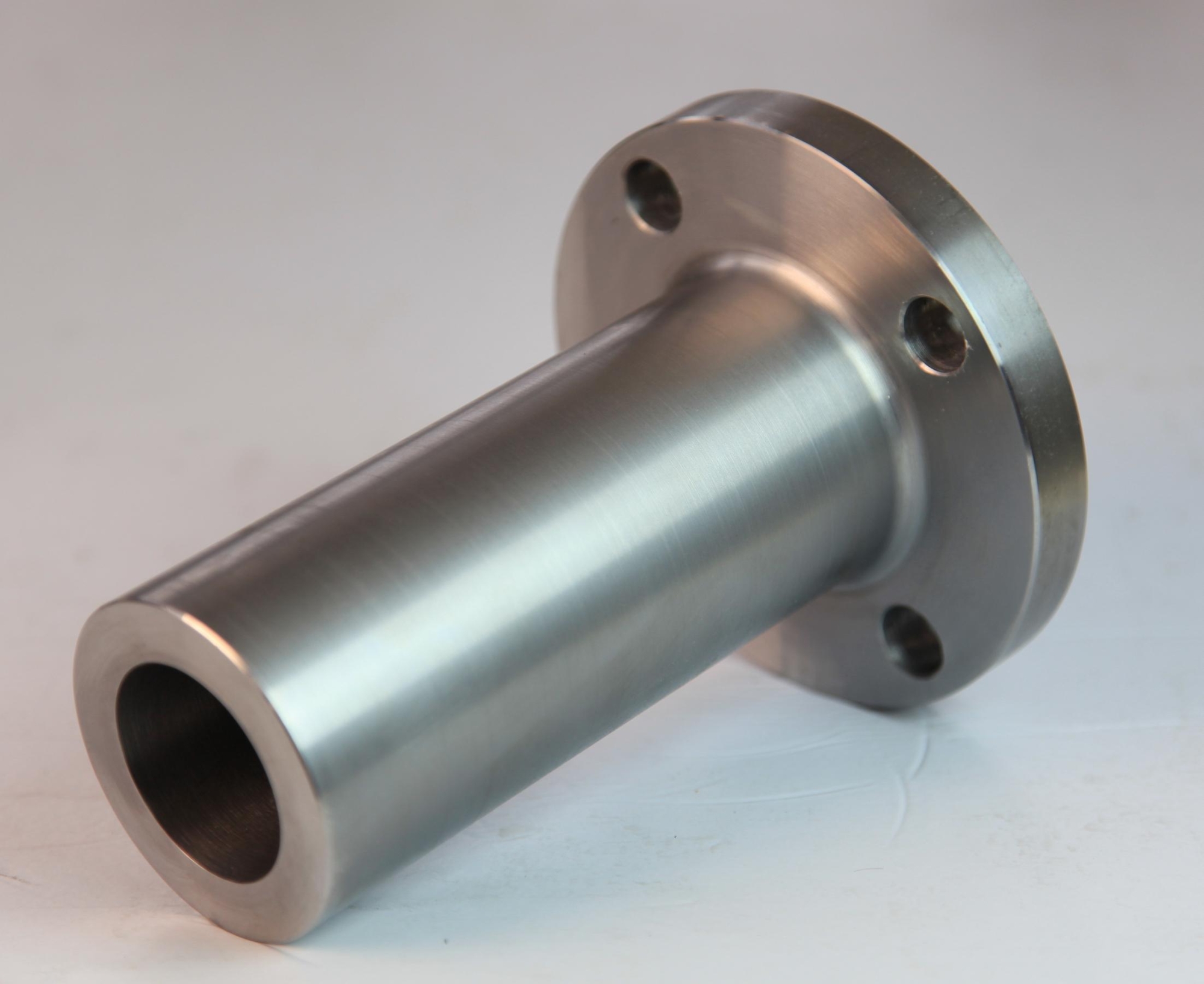

What is a Long Weld Neck Flange?

A long weld neck flange (LWN) is a type of flange featuring an extended, tapered neck that is welded directly to a pipe. Unlike standard weld neck flanges, the long neck design offers additional reinforcement, making it particularly suitable for applications involving extreme pressure, temperature, or cyclic loading.

The extended neck gradually distributes stress between the flange and the connected pipe, reducing localized stress concentrations and enhancing overall safety.

Key Features of Long Weld Neck Flanges:

-

Extended Neck: Provides structural strength and smooth stress transition.

-

Tapered Hub: Minimizes turbulence and erosion at the joint.

-

Butt Weld Connection: Ensures leak-proof performance.

-

High Strength: Suitable for demanding operating conditions.

-

Variety of Standards: Manufactured in compliance with ASME, ANSI, DIN, and EN specifications.

Dimensions and Standards

Long weld neck flanges are available in a wide range of pressure classes, typically from Class 150 to Class 2500, and in sizes ranging from ½ inch to 60 inches or more.

Common Standards:

-

ASME B16.5: For sizes up to 24 inches.

-

ASME B16.47: For larger sizes above 24 inches.

-

DIN/EN Standards: European specifications for various pressure ratings.

The neck length can be customized based on the application. In critical industries like oil and gas, custom designs are often specified to meet precise requirements.

Materials Used in Long Weld Neck Flanges

Long weld neck flanges are manufactured from various materials depending on the service environment:

-

Carbon Steel: Cost-effective, suitable for moderate conditions.

-

Stainless Steel (304, 316, 321, 347): Excellent corrosion resistance.

-

Alloy Steel: Enhanced strength and heat resistance.

-

Nickel Alloys (Inconel, Monel, Hastelloy): Exceptional resistance to aggressive chemicals and high temperatures.

-

Duplex and Super Duplex Stainless Steel: High strength combined with chloride stress corrosion resistance.

Manufacturing Process of Long Weld Neck Flanges

-

Forging: Raw steel billets are forged into the flange shape.

-

Heat Treatment: Normalizing, quenching, and tempering improve mechanical properties.

-

Machining: Precision machining ensures accurate dimensions.

-

Inspection: Ultrasonic testing, radiography, and PMI testing confirm quality.

-

Surface Finish: Anti-rust coatings or pickling enhance durability.

Applications of Long Weld Neck Flanges

Long weld neck flanges are used in industries where safety and reliability are critical:

-

Oil and Gas: Refineries, offshore platforms, subsea pipelines.

-

Petrochemical Plants: High-temperature and high-pressure chemical reactors.

-

Power Generation: Boilers, turbines, and nuclear power equipment.

-

Marine Engineering: Shipbuilding, desalination plants, offshore structures.

-

Aerospace and Defense: Specialized piping for test chambers and fuel systems.

Advantages of Long Weld Neck Flanges

-

Enhanced Strength: The extended neck provides superior reinforcement.

-

Stress Distribution: Tapered design reduces stress concentration.

-

Leak-Proof Connection: Butt weld ensures high integrity in critical systems.

-

Customizable Design: Neck length can be tailored to project specifications.

-

Durability: Resistant to fatigue and thermal expansion cycles.

Difference Between Weld Neck Flange and Long Weld Neck Flange

-

Weld Neck Flange: Standard short tapered hub, suitable for general piping.

-

Long Weld Neck Flange: Extended neck for greater strength, designed for severe service conditions.

While weld neck flanges are more common, long weld neck flanges are chosen for specialized, high-stress applications.

Testing and Quality Assurance

To ensure safe performance, long weld neck flanges undergo rigorous quality checks:

-

Hydrostatic testing.

-

Ultrasonic and radiographic inspection.

-

Mechanical property testing (tensile, yield, hardness).

-

Corrosion resistance testing.

-

Dimensional verification.

Future Trends in Flange Technology

As industries evolve, the demand for high-performance flanges is expected to grow. Emerging trends include:

-

Use of advanced alloys for extreme environments.

-

Integration of digital inspection techniques for real-time quality control.

-

Custom-engineered long weld neck flanges for renewable energy projects, such as offshore wind farms.

Conclusion

A long weld neck flange is a specialized flange with an extended neck, designed to provide additional reinforcement and stress distribution in high-pressure and high-temperature environments. It differs from standard weld neck flanges by offering enhanced durability and reliability, making it essential in oil and gas, petrochemical, power generation, and marine applications.

By understanding its design, benefits, and applications, engineers and procurement specialists can make informed decisions for their projects. With the right material and supplier, long weld neck flanges ensure safety, efficiency, and long-term performance in critical industrial systems. Contact us at +84 33 4233 127 or via email at sjmvina@sunjinmetal.com. Visit www.sjmvina.com.vn for more information and to place your order today!

Views: 70