- Importance in the Oil and Gas Industry

- Role in Construction and Manufacturing

- Applications in Power Generation

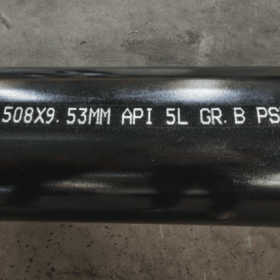

- Overview of API 5L Specifications

- API 5L Product Levels

- Pipe Manufacturing Processes

- Sizes and Dimensions of API 5L Pipes

- Delivery Conditions for API 5L Pipes

- Chemical and Mechanical Properties

- Testing Requirements for API 5L Pipes

- Applications of API 5L Pipes

- API 5L Grades and Their Significance

- Coating and Lining of API 5L Pipes

- International Standards and Equivalents

- Conclusion

API 5L pipes are vital components in the oil and gas, construction, manufacturing, and power generation industries. This comprehensive guide explores the specifications, grades, and applications of API 5L pipes, providing procurement managers, engineers, and project managers with essential information to make informed decisions. From understanding the various grades and their mechanical properties to examining their applications and benefits, this article serves as a valuable resource for professionals seeking reliable, high-quality piping solutions.

Sunjin Metals Vina (SJM Vina) is a trusted supplier of steel pipes, flanges, and fittings sourced from South Korea and other countries, ensuring compliance with international standards.

Importance in the Oil and Gas Industry

API 5L pipes play a critical role in the oil and gas industry. Designed to transport petroleum and natural gas over long distances, often through challenging environments, these pipes are built to withstand high pressures, extreme temperatures, and corrosive substances. Their robust construction and adherence to stringent standards ensure pipeline integrity, preventing leaks or failures that could result in environmental disasters and significant financial losses.

Role in Construction and Manufacturing

In the construction and manufacturing sectors, API 5L pipes are utilized for various structural applications. Their high strength and durability make them ideal for supporting heavy loads and enduring harsh conditions. Whether used in building frameworks, machinery, or infrastructure projects, these pipes provide essential support and stability. Their versatility enables their use across a wide range of applications, from residential buildings to large industrial complexes.

Applications in Power Generation

Power generation facilities rely on API 5L pipes for transporting steam, water, and other fluids. These pipes ensure efficient and reliable operation of power plants, contributing to consistent electricity production. The high-quality materials and advanced manufacturing processes used in API 5L pipes make them suitable for the demanding conditions of power generation environments, minimizing downtime and maintenance costs to ensure a stable power supply.

Overview of API 5L Specifications

What is API 5L?

API 5L is a specification developed by the American Petroleum Institute (API) for seamless and welded steel pipes used in pipeline transportation systems within the petroleum and natural gas industries. This specification covers various grades, including B, X42, X52, X60, X65, and X70, each with specific requirements for chemical composition, mechanical properties, and testing to ensure suitability for intended applications.

Historical Development of API 5L Standards

The API 5L standard has evolved over time to meet the growing demands of the industry. Initially established to provide consistent guidelines for pipeline construction, the standard has been updated to incorporate advancements in technology and materials. These updates have enhanced the performance and reliability of API 5L pipes, making them suitable for a broader range of applications and environments.

Key Features and Benefits

API 5L pipes offer several key features, including high strength, durability, and corrosion resistance. These properties make them ideal for harsh environments and long-term applications. Strict quality control measures and testing requirements ensure that the pipes meet safety and performance standards, which is crucial for maintaining pipeline integrity and preventing leaks or failures.

API 5L Product Levels

PSL1: Basic Quality Level

Chemical Composition

PSL1 pipes have a basic chemical composition that meets minimum requirements for standard pipeline applications. This includes specific limits on elements such as carbon, manganese, phosphorus, sulfur, and silicon, ensuring the necessary strength and durability for standard uses.

Mechanical Properties

PSL1 pipes provide adequate mechanical properties, including minimum yield strength, tensile strength, and elongation, ensuring reliable performance in standard pipeline applications. These properties allow the pipes to withstand operational pressures and stresses.

PSL2: Higher Quality Level

Enhanced Chemical Composition

PSL2 pipes have stricter chemical composition limits, ensuring higher quality and material consistency. Tighter controls on elements like carbon, manganese, phosphorus, sulfur, and silicon enhance the overall performance and reliability of the pipes.

Stricter Mechanical Properties

PSL2 pipes offer superior mechanical properties, including higher yield and tensile strength, making them suitable for more demanding applications with higher pressures and stresses. Stricter elongation requirements ensure they can withstand deformation without failure.

Additional Testing Requirements

PSL2 pipes undergo additional testing, such as the Charpy V-Notch (CVN) impact test, to ensure performance in extreme conditions. This test measures the pipe’s ability to absorb energy and resist fracture, ensuring reliability in harsh environments.

Pipe Manufacturing Processes

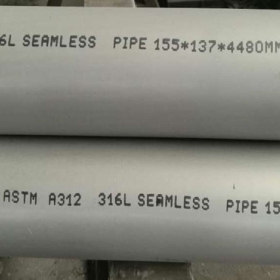

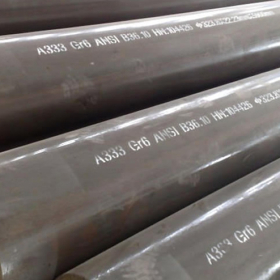

Seamless (SMLS) Pipes

Manufacturing Process

Seamless pipes are produced from solid round billets, which are heated and pierced to create a hollow tube. The process involves heating the billet, piercing it with a mandrel, and then rolling and stretching it to achieve the desired size and thickness, resulting in a pipe with a smooth, continuous surface and no welded seams.

Advantages and Disadvantages

Seamless pipes offer high strength and uniformity, with the absence of welded seams reducing the risk of defects. They are ideal for high-pressure applications but are generally more expensive and limited in size compared to welded pipes. The manufacturing process is complex and requires specialized equipment.

Electric Resistance Welded (ERW) Pipes

Manufacturing Process

ERW pipes are made by welding the edges of steel coils, creating a continuous seam along the pipe’s length. The process involves forming the steel coil into a cylindrical shape, welding the edges using electric resistance, and then sizing and finishing the pipe to the desired dimensions.

Advantages and Disadvantages

ERW pipes are cost-effective and available in larger sizes compared to seamless pipes. The manufacturing process is relatively simple and efficient, making them suitable for various applications. However, ERW pipes may have lower strength, and the weld seam can be a potential weak point if not properly inspected.

Double Submerged Arc Welded (DSAW) Pipes

Manufacturing Process

DSAW pipes are produced by welding both the inside and outside seams, providing additional strength and durability. The process involves forming a steel plate into a cylindrical shape, welding the edges with submerged arc welding, and then welding both seams, resulting in a pipe with a strong, double-welded seam.

Advantages and Disadvantages

DSAW pipes offer high strength and are suitable for large-diameter, high-pressure applications. The double-welded seam enhances durability, but the production process is more complex and costly compared to ERW pipes, requiring specialized equipment and skilled operators.

Sizes and Dimensions of API 5L Pipes

Seamless Pipe Sizes

Seamless pipes are available in sizes ranging from 2″ NPS to 36″ OD, offering flexibility for various projects. The range of sizes ensures that the appropriate pipe can be selected for specific project requirements.

ERW Pipe Sizes

ERW pipes are available in sizes from 2″ NPS to 24″ OD, suitable for both small-scale and larger industrial applications. The variety of sizes allows for tailored selections based on project needs.

DSAW Pipe Sizes

DSAW pipes are available in sizes from 20″ to 48″ OD, making them ideal for large-scale, heavy-duty applications. The range of sizes ensures suitability for specific project requirements.

Delivery Conditions for API 5L Pipes

PSL1 Delivery Conditions

PSL1 pipes can be delivered in as-rolled, normalized, or normalizing formed conditions, offering options based on project requirements. The as-rolled condition is the most basic, while normalized and normalizing formed conditions provide additional strength and durability.

PSL2 Delivery Conditions

PSL2 pipes must be delivered in a normalized condition to ensure consistent quality and performance, making them suitable for demanding applications where higher strength and durability are required.

Chemical and Mechanical Properties

Chemical Composition of PSL1 Pipes

PSL1 pipes have a basic chemical composition with specific limits on elements like carbon, manganese, phosphorus, sulfur, and silicon, ensuring adequate strength and durability for standard pipeline applications.

Mechanical Properties of PSL1 Pipes

PSL1 pipes provide sufficient mechanical properties, including yield and tensile strength, to ensure reliable performance in standard pipeline applications.

Chemical Composition of PSL2 Pipes

PSL2 pipes have stricter chemical composition limits, ensuring higher material quality and consistency, which enhances overall performance and reliability.

Mechanical Properties of PSL2 Pipes

PSL2 pipes offer superior mechanical properties, including higher yield and tensile strength, suitable for demanding applications with elevated pressures and stresses. Stricter elongation requirements ensure resistance to deformation.

Testing Requirements for API 5L Pipes

Charpy V-Notch (CVN) Impact Test

The CVN impact test, required for many PSL2 pipe sizes and grades, measures the pipe’s ability to absorb energy and resist fracture, ensuring performance in extreme conditions.

Non-Destructive Testing (NDT)

Ultrasonic Testing

Ultrasonic testing uses high-frequency sound waves to detect internal flaws, ensuring the pipe’s integrity and compliance with safety and performance standards.

Radiographic Testing

Radiographic testing provides detailed images of the pipe’s internal structure using X-rays or gamma rays, identifying defects or inconsistencies to ensure compliance with standards.

Hydrostatic Testing

Hydrostatic testing involves filling the pipe with water and applying pressure to verify its ability to withstand operational conditions, ensuring safety and performance standards are met.

Applications of API 5L Pipes

Onshore and Offshore Pipelines

API 5L pipes are used in onshore and offshore pipelines for transporting oil, gas, and water, ensuring safe and efficient transportation while maintaining pipeline integrity.

Sour Service Applications

Pipes used in environments containing hydrogen sulfide (H2S) must meet additional requirements specified in Annex H of API 5L, ensuring resistance to corrosion and cracking in sour service applications.

Offshore Service Applications

Pipes used in offshore environments must meet additional requirements specified in Annex J of API 5L, ensuring durability in harsh offshore conditions.

API 5L Grades and Their Significance

Understanding API 5L Grades

API 5L grades indicate the minimum yield strength of the pipe, with higher grades offering greater strength and performance. Each grade has specific requirements for chemical composition, mechanical properties, and testing.

Minimum Yield Strength

The minimum yield strength ranges from 42,000 psi for grade X42 to 70,000 psi for grade X70, providing options for various applications, from standard to demanding environments.

Common Grades: B, X42, X52, X60, X65, X70

Common API 5L grades include B, X42, X52, X60, X65, and X70, each offering different levels of strength and performance for specific applications.

Coating and Lining of API 5L Pipes

Importance of Coating and Lining

Coatings and linings protect API 5L pipes from corrosion and improve flow efficiency, extending their lifespan and ensuring long-term performance and reliability.

Types of Coatings and Linings

Available coatings and linings include epoxy, polyethylene, and fusion-bonded epoxy, each offering different levels of protection and performance for specific applications.

International Standards and Equivalents

Global Recognition of API 5L

API 5L is internationally recognized and equivalent to standards like ISO 3183, ensuring global acceptance and consistent guidelines for pipeline construction.

Equivalent Standards (ISO 3183, etc.)

Equivalent standards, such as ISO 3183, provide similar specifications for pipeline transportation systems, ensuring API 5L pipes meet safety and performance standards globally.

Conclusion

API 5L pipes are indispensable in the oil and gas, construction, manufacturing, and power generation industries. This detailed guide has provided insights into the specifications, grades, and applications of API 5L pipes, enabling procurement managers, engineers, and project managers to make informed decisions. By selecting the appropriate API 5L pipes for specific needs, professionals can ensure project success and longevity.

Sunjin Metals Vina proudly offers API 5L-compliant steel pipes, flanges, and fittings, manufactured to the highest standards. With superior quality, rigorous production processes, and exceptional customer service, we are your trusted partner for piping solutions. Contact us at +84 33 4233 127 or via email at sjmvina@sunjinmetal.com. Visit www.sjmvina.com.vn for more information and to place your order today!

Số lần xem: 128