- Overview of Pipe Elbows

- What is a 45-Degree Elbow?

- What is a 90-Degree Elbow?

- 45-Degree vs. 90-Degree Elbow: Main Differences

- Material Selection for Elbows

- Radius of Bend: Short vs. Long Radius

- Industrial Applications

- Installation Considerations

- Standards and Compliance

- Choosing Between 45-Degree and 90-Degree Elbows

- Maintenance and Longevity

- Conclusion

In the piping industry, elbows are among the most widely used fittings, serving the critical function of changing the direction of fluid flow. Depending on system requirements, elbows can be manufactured in various angles, materials, and pressure classes. The most common elbow types are the 45-degree elbow and the 90-degree elbow, each designed for specific flow and space considerations.

Understanding the differences between these two elbows is essential for engineers, designers, and maintenance teams to ensure optimal system performance and cost efficiency.

Sunjin Metals Vina (SJM Vina), is a trusted supplier of high-quality steel pipes, flanges, and fittings sourced from South Korea and other countries, fully compliant with international standards.

Overview of Pipe Elbows

A pipe elbow is a curved fitting that connects two pipes and alters the direction of flow. Unlike straight fittings such as couplings, elbows allow for bends in the pipeline layout without requiring complex pipe bending operations.

Elbows are classified by:

-

Angle of Bend: Commonly 45 degrees, 90 degrees, or 180 degrees.

-

Radius of Bend: Short radius (SR) or long radius (LR).

-

Connection Type: Butt-weld, socket weld, threaded.

-

Material: Carbon steel, stainless steel, alloy steel, or non-metallic.

What is a 45-Degree Elbow?

A 45-degree elbow changes the direction of the pipe by 45 degrees. It is typically used when a smaller degree of directional change is needed to navigate around obstacles or adjust alignment gradually.

Key Characteristics:

-

Provides a gentler change in flow direction compared to a 90-degree elbow.

-

Creates less turbulence and lower pressure drop.

-

Often used in pump suction and discharge lines to minimize flow resistance.

Advantages:

-

Reduced risk of erosion and pressure loss.

-

Smoother flow, beneficial in slurry or high-velocity applications.

-

Ideal for systems requiring gradual directional changes.

What is a 90-Degree Elbow?

A 90-degree elbow changes the direction of the pipe by 90 degrees, creating a right-angle turn. It is the most commonly used elbow type in piping systems.

Key Characteristics:

-

Creates a sharp directional change.

-

Used when space is limited or a tight turn is required.

-

Available in short radius and long radius designs.

Advantages:

-

Allows efficient use of space in tight layouts.

-

Offers versatility for both horizontal-to-vertical and vertical-to-horizontal flow changes.

-

Standardized design for easy replacement.

45-Degree vs. 90-Degree Elbow: Main Differences

1. Flow Dynamics

-

45-Degree Elbow: Causes less friction loss due to gradual direction change.

-

90-Degree Elbow: Produces higher turbulence and pressure drop due to the sharp turn.

2. Application Areas

-

45-Degree Elbow: Ideal for systems where maintaining high flow efficiency is critical.

-

90-Degree Elbow: Common in compact layouts where space is limited.

3. Pressure Considerations

-

45-Degree Elbow: Better for high-velocity flow where pressure loss must be minimized.

-

90-Degree Elbow: Suitable for low to moderate velocity systems or where directional change is more important than flow efficiency.

4. Cost

-

45-Degree Elbow: Slightly higher material and installation cost in some cases due to longer length.

-

90-Degree Elbow: Generally more economical and widely stocked.

Material Selection for Elbows

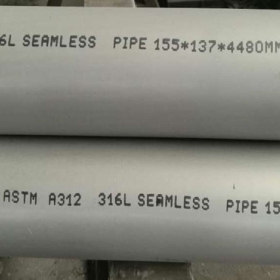

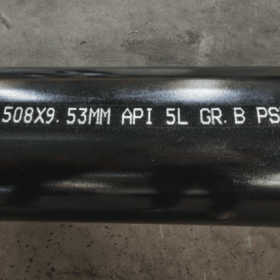

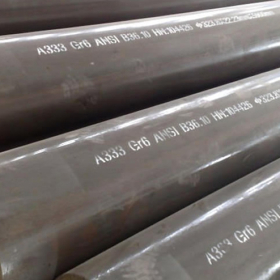

Elbows can be manufactured in:

-

Carbon Steel: Durable and cost-effective for general use.

-

Stainless Steel: Corrosion-resistant for chemical and food processing.

-

Alloy Steel: High-strength performance for elevated temperature applications.

-

Non-Metallic: PVC, CPVC, and HDPE for low-pressure systems.

Selecting the right material depends on the media being transported, operating temperature, and pressure rating.

Radius of Bend: Short vs. Long Radius

Both 45-degree and 90-degree elbows come in short radius (SR) and long radius (LR) designs:

-

Short Radius: Compact design, tighter turn, higher pressure drop.

-

Long Radius: Smoother flow, lower pressure loss, requires more installation space.

Industrial Applications

1. Oil and Gas

-

45-Degree Elbows: Used in crude oil pipelines to reduce erosion from particulate matter.

-

90-Degree Elbows: Installed in offshore platforms with limited space.

2. Chemical Processing

-

45-Degree Elbows: Prevent sudden directional changes that could damage sensitive materials.

-

90-Degree Elbows: Direct flow in complex plant layouts efficiently.

3. Water Treatment

-

45-Degree Elbows: Improve hydraulic efficiency in pump systems.

-

90-Degree Elbows: Allow space-saving designs in distribution lines.

4. HVAC Systems

Both elbows are used to direct chilled or hot water through complex building piping networks.

Installation Considerations

-

Ensure proper alignment to avoid stress on the pipeline.

-

Select the correct radius to match flow requirements and space constraints.

-

Use compatible gaskets and fasteners for flanged elbows.

-

For welded elbows, ensure proper bevel preparation and welding standards compliance.

Standards and Compliance

Elbows are manufactured according to standards such as:

-

ASME B16.9: Factory-made wrought butt-welding fittings.

-

ASME B16.11: Forged fittings, socket-welding, and threaded.

-

MSS-SP-75: High-strength butt-weld fittings.

-

DIN/ISO: International equivalents.

Compliance ensures dimensional accuracy, material integrity, and safe operation.

Choosing Between 45-Degree and 90-Degree Elbows

Choose 45-Degree Elbows When:

-

Smooth flow is essential.

-

Minimizing pressure loss is critical.

-

Space allows for a longer fitting.

Choose 90-Degree Elbows When:

-

A sharp turn is needed in limited space.

-

System layout requires compact connections.

-

Cost and availability are key priorities.

Maintenance and Longevity

Both types of elbows have a long service life when made from the correct material and installed properly. Regular inspections should check for:

-

Corrosion.

-

Erosion from abrasive flow.

-

Weld integrity.

-

Mechanical damage.

Conclusion

The difference between a 45-degree elbow and a 90-degree elbow lies primarily in the degree of directional change, flow characteristics, and application suitability. The 45-degree elbow offers smoother flow with less turbulence, making it ideal for high-efficiency systems. The 90-degree elbow, on the other hand, is compact and versatile, fitting into tight spaces where a sharp turn is required.

Sunjin Metals Vina provides both 45-degree and 90-degree elbows in a variety of materials, pressure ratings, and sizes, manufactured to international standards to ensure performance, safety, and durability in every application. Contact us at +84 33 4233 127 or via email at sjmvina@sunjinmetal.com. Visit www.sjmvina.com.vn for more information and to place your order today!

Số lần xem: 177