Stainless steel is a widely used metal material in various industries, including construction, chemical, medical, and industrial applications, due to its corrosion resistance, high-temperature tolerance, and aesthetic appeal. Among the many types of stainless steel, 304 and 316 are the most common. But what are the differences between these two types, and how do you choose the right one for your specific application? This article provides a detailed analysis of the key differences between 304 and 316 stainless steel, covering chemical composition, corrosion resistance, strength, magnetism, and cost, helping engineers, procurement managers, and project professionals make informed decisions.

Sunjin Metals Vina (SJM Vina) is a trusted supplier of stainless steel pipes, flanges, and fittings sourced from South Korea and other countries, ensuring compliance with international standards.

Overview of 304 and 316 Stainless Steel

Both 304 and 316 stainless steel belong to the austenitic stainless steel family, renowned for their corrosion resistance, high strength, and versatility in various applications. However, they differ in chemical composition and technical properties, leading to variations in performance and intended uses. Understanding these differences is critical for selecting the appropriate stainless steel for projects ranging from industrial piping systems to applications in harsh environments like marine or chemical settings.

Below is a detailed analysis of the key differences between 304 and 316 stainless steel based on essential factors.

1. Chemical Composition

The chemical composition of 304 and 316 stainless steel significantly impacts their corrosion resistance and other properties.

-

304 Stainless Steel: Contains approximately 18% chromium and 8% nickel (often referred to as 18/8 stainless steel). This composition provides good corrosion resistance in standard environments, such as air or fresh water. However, 304 does not contain molybdenum, making it less effective in highly corrosive environments like saltwater or acidic conditions.

-

316 Stainless Steel: Contains approximately 16% chromium, 10% nickel, and 2% molybdenum. The addition of molybdenum is the key factor enhancing 316’s superior corrosion resistance, particularly in chloride-rich environments (such as seawater) or acidic conditions. This makes 316 ideal for marine and chemical industry applications.

The presence of molybdenum in 316 stainless steel is the primary factor driving its performance advantage over 304.

2. Corrosion Resistance

Corrosion resistance is one of the most critical factors when comparing 304 and 316 stainless steel.

-

304 Stainless Steel: Offers good corrosion resistance in standard environments, such as indoor settings, fresh water, or air. However, it is susceptible to chloride-induced corrosion, particularly in saltwater or coastal areas, limiting its use in highly corrosive environments.

-

316 Stainless Steel: Thanks to the addition of molybdenum, 316 stainless steel provides superior corrosion resistance, especially against chloride corrosion and in acidic environments. This makes it the preferred choice for applications in marine settings, saltwater pools, chemical plants, and systems handling corrosive fluids.

The enhanced corrosion resistance of 316 makes it more suitable for harsh environments, while 304 is a cost-effective option for less demanding applications.

3. Strength and Hardness

Strength and hardness are crucial considerations for applications requiring mechanical performance and wear resistance.

-

304 Stainless Steel: Provides adequate strength and hardness for many standard applications, such as piping systems, kitchen equipment, or construction structures. However, it is not optimized for applications requiring high strength or significant mechanical stress.

-

316 Stainless Steel: Due to the addition of molybdenum, 316 stainless steel offers higher strength and hardness compared to 304. This makes it suitable for applications requiring greater pressure resistance, wear resistance, or mechanical stress, such as in shipbuilding, chemical equipment, or heavy industrial systems.

316 stainless steel is often chosen for environments demanding superior mechanical performance compared to 304.

4. Magnetism

The magnetic properties of stainless steel can influence material selection in certain applications, particularly in industries like electronics or medical equipment.

-

304 Stainless Steel: Is non-magnetic in its annealed state, making it ideal for applications requiring non-magnetic materials, such as medical devices or electronic components.

-

316 Stainless Steel: In its annealed state, 316 is also nearly non-magnetic. However, during cold working, 316 may develop a slight degree of magnetism due to the presence of molybdenum. Despite this, 316 is generally considered non-magnetic for most applications.

While the difference in magnetism is typically not a deciding factor, it should be considered for applications sensitive to magnetic properties.

5. Cost

Cost is a significant factor when choosing between 304 and 316 stainless steel, especially for projects with budget constraints.

-

304 Stainless Steel: Is more cost-effective due to its simpler chemical composition, lacking molybdenum. This makes 304 a preferred choice for applications where high corrosion resistance is not required, such as in construction or household appliances.

-

316 Stainless Steel: Due to its higher nickel content and the addition of molybdenum, 316 is more expensive than 304. The higher cost reflects its superior performance in harsh environments but may not be necessary for standard applications.

When selecting materials, balancing cost with technical requirements is essential to achieve both economic efficiency and optimal performance.

6. Practical Applications

The differences between 304 and 316 stainless steel lead to distinct applications in various industries:

-

304 Stainless Steel: Commonly used in applications such as:

-

Low-pressure water and gas piping systems.

-

Kitchen equipment, such as sinks and cookware.

-

Construction structures, like railings and door frames.

-

Decorative applications due to its aesthetic appeal.

-

-

316 Stainless Steel: Preferred for applications requiring high corrosion resistance, such as:

-

Piping systems in marine environments or saltwater.

-

Chemical and pharmaceutical equipment exposed to acids or corrosive substances.

-

Shipbuilding and offshore structures.

-

Heavy industrial applications requiring high strength and wear resistance.

-

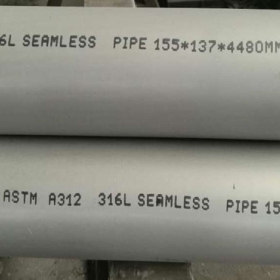

SJM Vina provides both 304 and 316 stainless steel in the form of seamless pipes, welded pipes, flanges, and fittings, meeting diverse technical requirements.

7. Choosing Between 304 and 316 Stainless Steel

When deciding between 304 and 316 stainless steel, consider the following factors:

-

Operating Environment: For marine, saltwater, or acidic environments, 316 is the better choice due to its superior corrosion resistance. For standard environments, 304 is often sufficient.

-

Mechanical Requirements: If higher strength and hardness are needed, 316 is preferable.

-

Magnetism: For applications requiring non-magnetic materials, 304 has a slight advantage, though 316 is also nearly non-magnetic in most cases.

-

Budget: 304 is more cost-effective, making it suitable for projects where corrosion resistance or high strength is not critical.

SJM Vina assists customers in selecting the appropriate stainless steel based on technical requirements, application, and budget. We provide products meeting international standards, accompanied by comprehensive technical documentation and quality certifications.

Conclusion

Both 304 and 316 stainless steel are essential materials in various industries, but they serve different purposes. 304 is ideal for general applications with lower costs, while 316 excels in harsh environments due to its superior corrosion resistance and strength. Understanding the differences in chemical composition, corrosion resistance, strength, magnetism, and cost is key to selecting the right material for your project.

Sunjin Metals Vina proudly supplies 304 and 316 stainless steel pipes, flanges, and fittings compliant with international standards. With superior quality, rigorous manufacturing processes, and exceptional customer service, we are your trusted partner for project solutions. Contact us at +84 33 4233 127 or via email at sjmvina@sunjinmetal.com. Visit www.sjmvina.com.vn for more information and to place your order today!

Số lần xem: 115