SJM Vina – Vietnam’s Leading Supplier of High-Quality Piping material

WHO WE ARE

SUNJIN METALS VINA

Established in 2018 in Ho Chi Minh City, Vietnam, Sunjin Metals Vina specializes in importing and supplying industrial piping materials, fittings, flanges, and valves from Korea, Japan, and other advanced industrial countries.

We deliver products that meet stringent manufacturing standards and proven reliability for the Oil & Gas, Chemical, Energy, and Industrial Plant.

READ MOREWhy Choose Us?

With many years of experience in the industry, we are confident in delivering the best value to contractors and project investors.

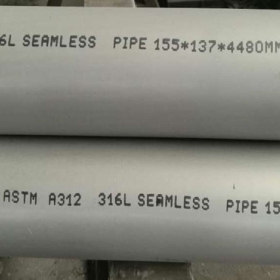

In the industrial metal supply sector, 316L stainless steel is among the most preferred grades due to its exceptional corrosion resistance. However, when examining technical specifications, users often encounter two designations: TP316L and 316L. While both are low-carbon variants of the popular 316 grade, subtle yet critical differences exist between them that directly impact operational performance in real-world applications. At Sunjin Metals Vina (SJM Vina), we specialize in importing stainless steel pipes, flanges, and fittings from South Korea and Japan, helping our clients understand material nuances to make the most accurate choice.

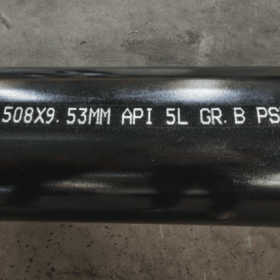

API 5L Grade B steel pipe is one of the most widely used materials in the oil and gas industry, prized for its perfect balance of strength and workability. One of the most critical factors when selecting steel pipes for any project is understanding the pressure rating. This rating is not a fixed value but varies based on wall thickness, diameter, and the manufacturing process. At Sunjin Metals Vina (SJM Vina), we specialize in importing and supplying high-quality API 5L Grade B pipes from South Korea, Japan, and other reputable nations, ensuring compliance with the most rigorous technical standards for our clients' operational systems.

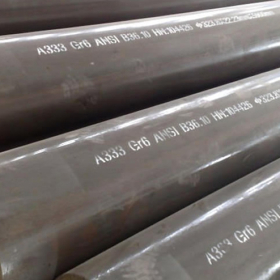

In the piping industry, selecting the correct material standard is a critical factor that determines the safety and longevity of a system. Among the most common standards today, A106 and A333 are two specifications that frequently cause confusion for users. Although both are industrial steel pipes, they possess entirely different chemical and mechanical properties. Sunjin Metals Vina (SJM Vina), a specialist in importing steel pipes and fittings from South Korea and Japan, shares the following in-depth insights to help you distinguish between these two materials.

Pipelines serve as the indispensable backbone of the oil and gas industry, ensuring the secure and continuous transport of vital fluids. From crude oil and natural gas to refined petroleum products, robust piping infrastructure facilitates the movement of energy essentials from extraction sites to refineries and ultimately to the global market. At Sunjin Metals Vina (SJM Vina), we understand that selecting the appropriate pipe material is critical to project integrity. SJM Vina specializes in importing high-grade steel pipes, flanges, and fittings from South Korea, Japan, and other leading industrial nations to provide optimized solutions for your infrastructure needs.

In the field of civil and industrial engineering, SGP steel pipe is one of the most widely used materials due to its versatility and reliability in low-pressure fluid conveyance. At Sunjin Metals Vina (SJM Vina), we provide a comprehensive range of SGP steel pipes imported directly from Japan, South Korea, and other reputable markets, ensuring superior quality for every project.

In the oil, gas, and energy transportation industries, selecting the right piping is a decisive factor for both operational efficiency and project safety. API 5L steel pipes are the industry standard, recognized for their superior load-bearing capacity and durability in extreme environments. At Sunjin Metals Vina (SJM Vina), we specialize in importing and distributing high-quality API 5L pipes from South Korea, Japan, and other leading manufacturing nations, meeting the most rigorous technical demands of our clients.

ASTM A105 is the standard specification for forged carbon steel components developed by the American Society for Testing and Materials (ASTM). This material is designed exclusively for the manufacture of piping system components such as flanges, valves, and high-pressure fittings.

In industrial piping systems, flanges play a critical role by securely connecting pipes, valves, pumps, and other equipment. They ensure tight sealing, mechanical stability, and easy disassembly for maintenance.

To guarantee proper identification and compliance with international standards, every flange is marked with detailed information, including standard, pressure rating, material, and manufacturing data. These markings are not just identification codes – they are essential for quality control, traceability, and system safety.

In modern hydraulic systems, where fluids are transmitted under extreme pressure, every component plays a vital role in ensuring overall performance and safety. Among these components, steel flanges are indispensable. They are used to connect pipes, valves, pumps, and other equipment, creating a secure and leak-proof joint that withstands both high pressure and temperature.

Today, Korean steel flanges have gained strong recognition in the industrial market thanks to their superior quality, durability, and compliance with strict international standards. Their exceptional ability to endure high pressure makes them an ideal solution for hydraulic systems and other demanding industrial applications.

In industries operating in marine and coastal environments, the durability and resistance of materials to corrosion are critical factors in ensuring safety and long-term performance. Among the most essential components in pipeline systems for marine applications are steel flanges, which connect pipes, valves, and fittings. For environments exposed to seawater, Korean steel flanges have proven to be an optimal solution due to their superior quality, corrosion resistance, and compliance with international standards.

In modern industries, pipeline systems are required to operate under increasingly complex and demanding conditions. From oil and gas, petrochemicals, power plants, to marine engineering, the performance and safety of pipeline connections play a critical role in ensuring stability and minimizing risks. Among the essential components of these systems, Korean steel flanges stand out for their superior leak-proof properties in high-pressure environments, helping businesses optimize operations while ensuring compliance with safety standards.

In industrial systems, especially in the oil and gas, energy, chemical, and construction sectors, steel flanges play a vital role in connecting pipelines, equipment, and valves. To ensure safety and operational efficiency, flange products must strictly comply with national and international quality standards. Among these, the KS (Korean Standards) system stands out as a benchmark widely applied to Korean steel flanges, ensuring stability, safety, and long-term durability.

Pipe Wall Thickness Calculator (ASME B31.3)

In industrial systems, boilers play a crucial role in generating steam, heat, and energy for various production processes. These systems operate under extreme conditions, including high temperatures, elevated pressure, and long continuous working hours. Therefore, all piping materials and connection components must meet strict standards of strength, durability, and safety.

In industrial piping systems, pipe fittings play a vital role in connecting pipelines, changing flow direction, branching, or adjusting pressure. To ensure safety, efficiency, and durability, these fittings must comply with strict international and regional standards. Among them, KS (Korean Standards), JIS (Japanese Industrial Standards), and ASTM (American Society for Testing and Materials) are the three most recognized systems applied to Korean pipe fittings.

At Sunjin Metals Vina (SJM Vina), we specialize in supplying Korean steel pipes, Korean steel flanges, and Korean pipe fittings, all manufactured in compliance with these standards to serve key industries such as oil & gas, chemical processing, power generation, and construction.

In the oil & gas sector, steel pipes and pipeline accessories form the foundation of safe, durable, and efficient pipeline systems. Among them, Korean steel flanges are highly valued for their superior quality, precise manufacturing, and ability to meet stringent international standards.

At Sunjin Metals Vina (SJM Vina), we specialize in supplying Korean steel pipes, Korean steel flanges, and Korean pipe fittings, serving industrial projects, especially in the oil & gas industry, with a strong commitment to quality and professional service.

In industrial construction, steel pipes play a vital role in creating durable, stable, and safe structural systems for large-scale projects. With outstanding advantages in quality, load-bearing capacity, and durability in harsh environments, Korean steel pipes have increasingly become the preferred choice for contractors and investors in Vietnam.

At Sunjin Metals Vina (SJM Vina), we specialize in supplying Korean steel pipes, Korean steel flanges, and Korean pipe fittings that fully comply with international standards, providing optimal solutions for industrial construction projects.

In the oil and gas industry, piping systems must operate under extreme conditions with high pressure, fluctuating temperatures, and corrosive environments. To ensure safety and efficiency, high-pressure Korean pipe fittings are considered the optimal choice thanks to superior quality, strict international standards, and long-term reliability.

At Sunjin Metals Vina (SJM Vina), we specialize in supplying Korean steel pipes, Korean steel flanges, and Korean pipe fittings that meet the most demanding requirements of onshore and offshore oil and gas projects.

In modern industries such as oil & gas, petrochemical, power generation, and shipbuilding, Korean steel flanges, pipes, and fittings are trusted for their high precision, durability, and compliance with international standards. Among them, the production technology of Korean steel flanges plays a decisive role in ensuring product quality and operational safety.

At Sunjin Metals Vina (SJM Vina), we specialize in supplying Korean-origin steel pipes, flanges, and fittings, manufactured under strict technological processes that meet global requirements. In this article, we will provide an in-depth look at two primary production methods of steel flanges: forging and casting, highlighting their characteristics and advantages.

Pipe Pressure Calculator (Công cụ tính áp suất ống)

Steel Pipe Weight Calculator

Flange bolting plays a critical role in ensuring the integrity of piping systems. Improper installation is the most common cause of leaking joints, which can lead to costly downtime, safety risks, and operational inefficiencies. At Sunjin Metals Vina (SJM Vina), we provide Korean-origin steel pipes, flanges, and fittings for industrial projects, and we emphasize that proper flange bolting procedures must always be followed. Below is a comprehensive guide to the correct procedure for flange bolting.

In industrial piping systems, international standards ensure consistency, safety, and compatibility for flange connections. One of the most widely adopted European flange standards is EN 1092. This standard defines the dimensions, tolerances, pressure ratings, and surface finishes for various flange types used in industrial pipelines across the European Union (EU) and beyond.

This article provides a comprehensive explanation of the EN 1092 flange standard, the types of flanges it encompasses, and its significance in today’s engineering and manufacturing industries.

Sunjin Metals Vina (SJM Vina), is a trusted supplier of high-quality steel pipes, flanges, and fittings sourced from South Korea and other countries, fully compliant with international standards.

In piping systems and industrial connections, selecting the appropriate flange type is critical to ensure leak-proof, pressure-resistant, and structurally sound joints. One of the key considerations in flange selection is the flange facing type. The two most common facing types are Raised Face (RF) and Flat Face (FF) flanges.

Understanding the differences between Raised Face and Flat Face flanges is essential for engineers, procurement teams, and maintenance professionals. This article provides a detailed explanation of the characteristics of each flange face type, their advantages, applications, and how to choose the right one for your project.

Sunjin Metals Vina (SJM Vina), is a trusted supplier of high-quality steel pipes, flanges, and fittings sourced from South Korea and other countries, fully compliant with international standards.

ASTM A105/A105M is a critical standard issued by the American Society for Testing and Materials (ASTM), specifying requirements for forged carbon steel used in the manufacture of pipe flanges, valves, fittings, and other high-pressure components. Known for its excellent mechanical properties and cost-effectiveness, this material is widely used in industries such as oil and gas, chemical, power, and construction. This article provides a detailed overview of the ASTM A105 standard, covering its chemical composition, mechanical properties, manufacturing processes, applications, and key considerations for material selection, assisting engineers, procurement managers, and project professionals in making informed decisions.

Sunjin Metals Vina (SJM Vina) is a trusted supplier of steel pipes, flanges, and fittings sourced from South Korea and other countries, ensuring compliance with international standards.

Stainless steel is a widely used metal material in various industries, including construction, chemical, medical, and industrial applications, due to its corrosion resistance, high-temperature tolerance, and aesthetic appeal. Among the many types of stainless steel, 304 and 316 are the most common. But what are the differences between these two types, and how do you choose the right one for your specific application? This article provides a detailed analysis of the key differences between 304 and 316 stainless steel, covering chemical composition, corrosion resistance, strength, magnetism, and cost, helping engineers, procurement managers, and project professionals make informed decisions.

Sunjin Metals Vina (SJM Vina) is a trusted supplier of stainless steel pipes, flanges, and fittings sourced from South Korea and other countries, ensuring compliance with international standards.

In the steel pipe industry, ASTM A53 and ASTM A106 are two critical standards for carbon steel pipes, particularly those used in demanding applications. While both standards share some similarities, they differ significantly in terms of intended applications, manufacturing processes, and chemical composition. This article provides a detailed analysis of the key differences between ASTM A53 and ASTM A106 steel pipes, assisting engineers, procurement managers, and project professionals in making informed material choices.

Sunjin Metals Vina (SJM Vina) is a trusted supplier of steel pipes, flanges, and fittings sourced from South Korea and other countries, ensuring compliance with international standards.

API 5L pipes are vital components in the oil and gas, construction, manufacturing, and power generation industries. This comprehensive guide explores the specifications, grades, and applications of API 5L pipes, providing procurement managers, engineers, and project managers with essential information to make informed decisions. From understanding the various grades and their mechanical properties to examining their applications and benefits, this article serves as a valuable resource for professionals seeking reliable, high-quality piping solutions.

Sunjin Metals Vina (SJM Vina) is a trusted supplier of steel pipes, flanges, and fittings sourced from South Korea and other countries, ensuring compliance with international standards.

In the piping industry, elbows are among the most widely used fittings, serving the critical function of changing the direction of fluid flow. Depending on system requirements, elbows can be manufactured in various angles, materials, and pressure classes. The most common elbow types are the 45-degree elbow and the 90-degree elbow, each designed for specific flow and space considerations.

Understanding the differences between these two elbows is essential for engineers, designers, and maintenance teams to ensure optimal system performance and cost efficiency.

Sunjin Metals Vina (SJM Vina), is a trusted supplier of high-quality steel pipes, flanges, and fittings sourced from South Korea and other countries, fully compliant with international standards.

In the realm of piping and flange systems, understanding Nominal Pipe Size (NPS) and Outer Diameter (OD) is essential for engineers, technicians, and procurement professionals. However, confusion often arises when converting between NPS and OD, particularly when dealing with international standards, technical drawings, or flange selection.

This comprehensive article explains how to convert flange NPS to OD, why it matters, and how to avoid errors during flange sourcing and installation. Sunjin Metals Vina (SJM Vina) supports global customers with accurate flange dimensioning, custom manufacturing, and expert technical consultation.